Fender removed.

Installing bump strips, etc

Fender installed.

More Oscilloscope work.

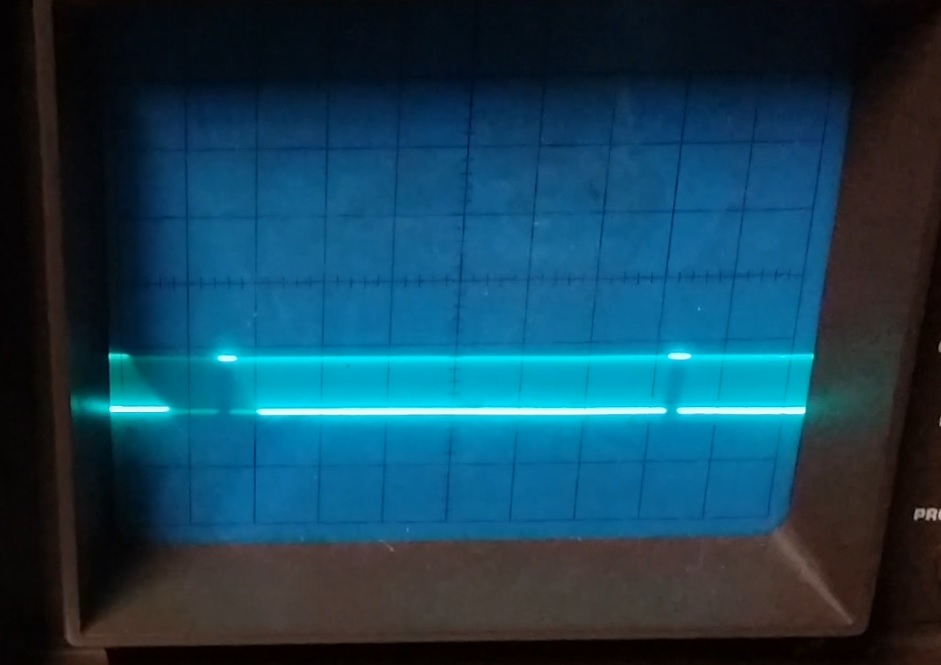

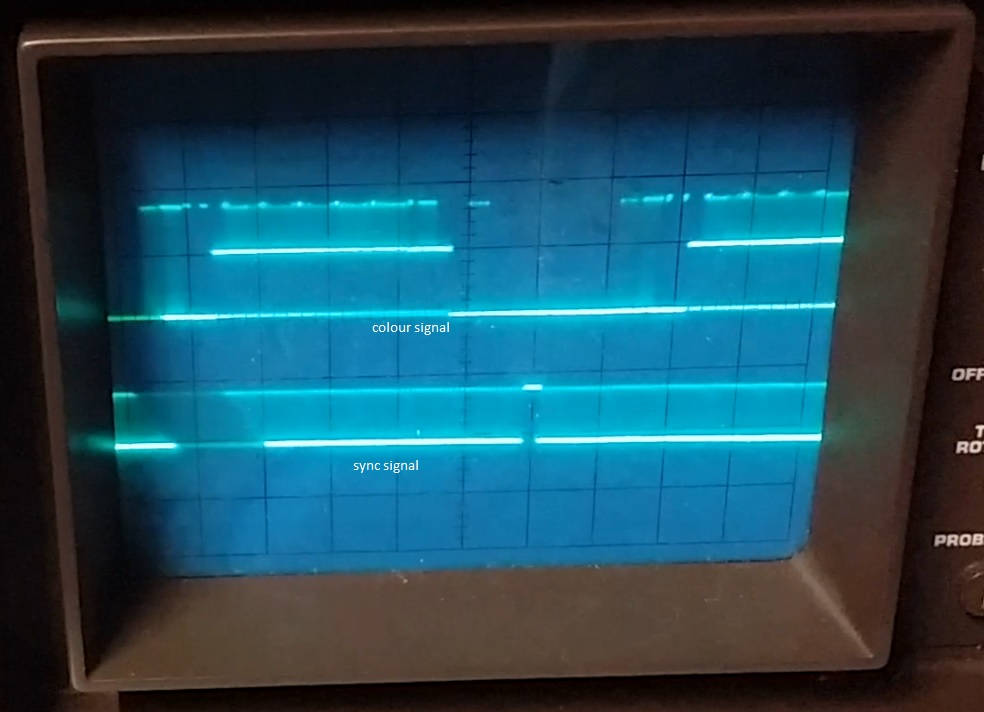

The whole screen represents 20ms, divisions are 2ms Voltage divisions are 2V.

Oscilloscope output of the sync signal

Oscilloscope output of the sync and colour signal

Links to videos.

Starting state. Everything pretty rusty.

Phosphoric acid tube

Phosphoric acid tube

One week later, nice and clean. With old rust part for comparison.

After painting everything gets put back together

New hardware

Almost done,

Finished product!

Info:

http://books.google.com.au/books?id=53nnX4fnnNIC&pg=PA220&lpg=PA220&dq=b-y%2C+r-y%2C+g-y+chroma&source=bl&ots=1udP3jnpaL&sig=rntO3MGxEeoK2435_mruSWo6zhs&hl=en&sa=X&ei=qFxzU_LKLIyPlQWxt4DwCw&ved=0CCgQ6AEwAA#v=onepage&q=b-y%2C%20r-y%2C%20g-y%20chroma&f=false

There seems to be 2 circuit paths:

One that takes R-Y, B-Y, G-Y and Y and then matrices the Y into the R-Y, B-Y, G-Y. This is done apparently so that the amount of Y added can be adjusted per colour. The output of this circuit goes into the R, G, B pins on the electrode gun. There are two more pins for earth and a heater?

The other takes the Sync and Power. There appear to be 3 syncs. SY, DH, DV. These are used to control the CRT deflectors.

So...

Feeding RGB + Ground from the CRT circuit and SY from the Input into the RGBS input of the converter produced no result. But I could have ruined up the CRT circuit when I was removing it.

EMV Computers: http://mz12gt.com/?p=293

Plan:

EMV Signal -> Converter Box -> ALR-1400 Controller -> 5.7" TFT

Parts:

Signal Interpreter: www.arcadespareparts.com/arcade_parts/video_converter/rgb_jamma_vga_converter_board/13052.html

ALR-1400 LCD Controller: http://www.digitalview.com/products/alr-1400-tech-specs

LCD Display: http://www.sharp.net.au/cms/articles/439/files/LQ057V3DG02%20LED%20BL%20%28TL%29.PDF

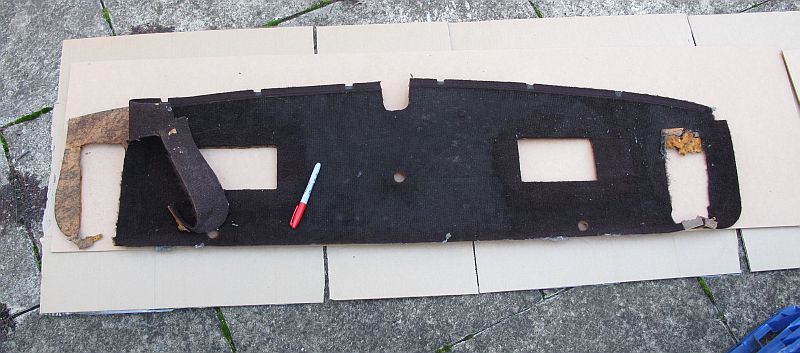

All the back seat parts disassembled for cleaning

The back seat restored with stacks of Lanolin grease and Connolly Hide Care.

Begin installing everything

Back in place.

If you can't buy it, you have to rebuild it.

Removing condenser bracketry

Condenser bracketry

Prepping for spray painting.

New and old condensers.

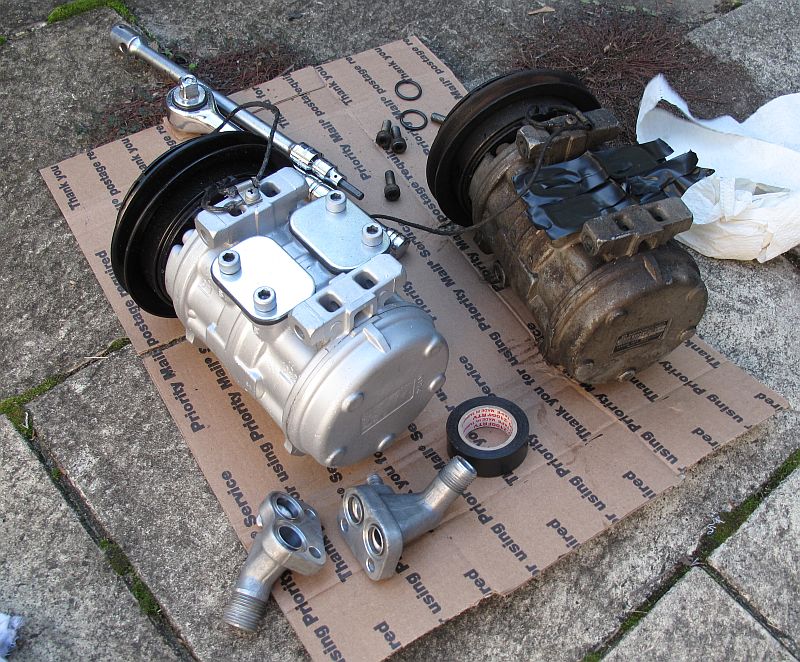

Moving across the service valves to the new compressor.

New compressor installed.

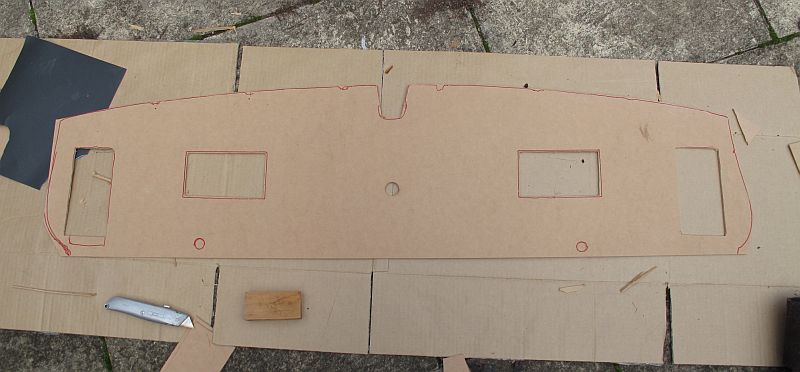

Materials:

- 140cm x 50cm 3mm MDF

- 140cm x 50cm Padding

- 140cm x 50cm Carpet

Equipment

- Stanley knife

- Metal ruler

- 25mm hole punch

Drawing up the template.

Cutting out the new board.

Shelf board finished

Padding adhered.

Test fitment.

Carpet added

Final fitting.

Had to scrap the MZ11. But took time to remove everything from it before letting it go.

Rear TEMS

Front TEMS

Wanted to keep the old technics speakers, but they were too far gone. Replaced with Sonys.

Passenger side door prepared, with handles and lock connections installed.

Driver side door prepared, with handles and lock connections installed.

Door-card cleaned with Connoly Hide care. Ready to be installed.

Put back the 1 Yen where I found it when I removed everything

New carpet underfill.

Original carpet installed.

All the wiring under the dash done.

The repaired crash pad.

Everything cleaned and installed on the crashpad

Everything installed.

For future reference. All th nuts and bolts that remain to be installed to hold it all in place.